Employment Application Apply

2026 Best Pfaudler Wiped Film Evaporator Features and Benefits Explained?

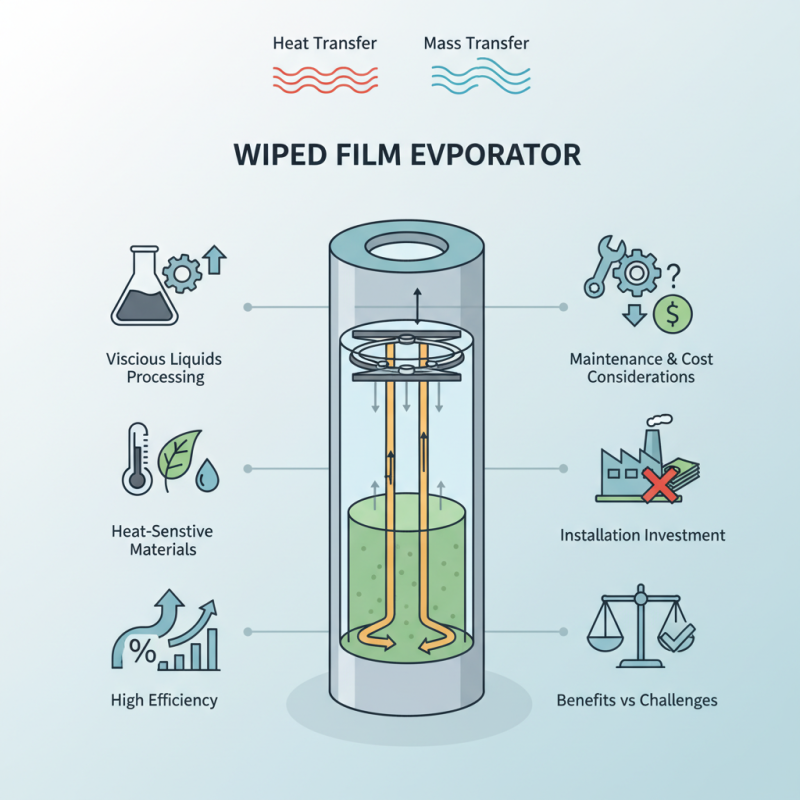

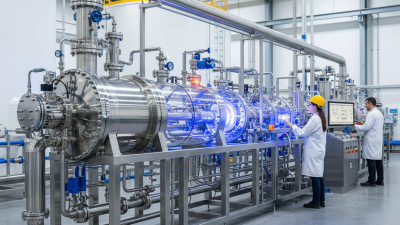

The Pfaudler wiped film evaporator stands out in the world of industrial evaporation technologies. Its advanced design offers unique features that enhance efficiency and product quality. This equipment is crucial for processes requiring simultaneous heat and mass transfer, especially in sensitive materials.

Efficiency is key in modern manufacturing. The Pfaudler wiped film evaporator excels in this area. Its ability to handle viscous liquids makes it versatile for many applications. However, operators must understand its limitations and ensure proper maintenance to maximize performance.

Many users appreciate the evaporator's ability to process heat-sensitive substances without degradation. Yet, installation and operational costs can be a concern for some. It is essential to weigh these factors when choosing this technology. The Pfaudler wiped film evaporator is a significant investment, making it crucial to analyze its benefits and potential challenges.

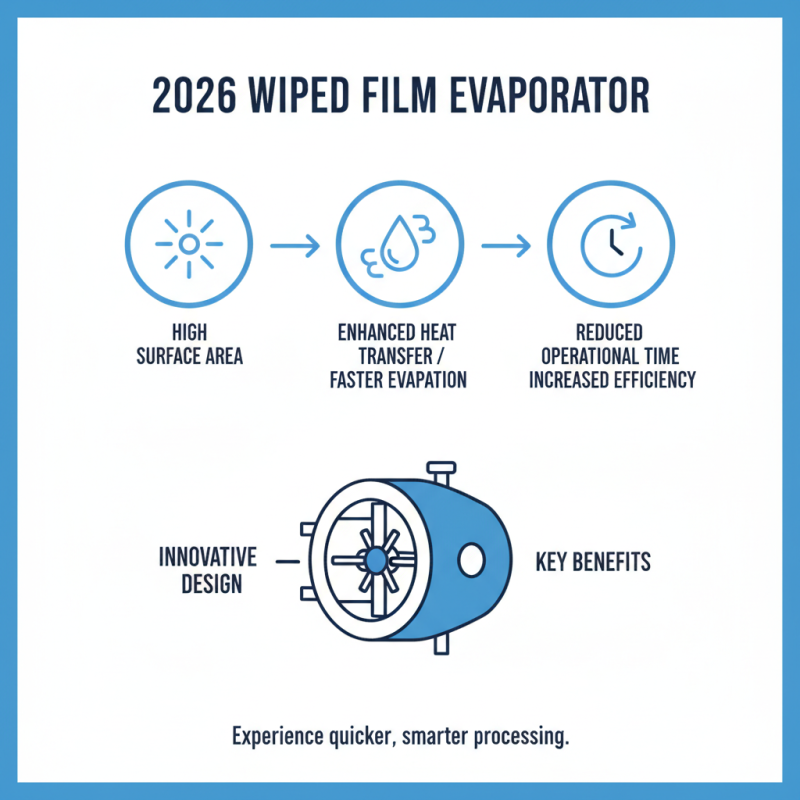

Key Features of the 2026 Pfaudler Wiped Film Evaporator

The 2026 wiped film evaporator presents innovative features that enhance its efficiency. Its design includes a high surface area, which allows for better heat transfer. This improves the evaporation rate, making the process quicker. Users often report reduced operational time thanks to this efficiency.

Another vital aspect is its automated system. Automation minimizes human error and boosts consistency. However, some operators find the initial setup challenging. Training may be necessary to ensure proper use. The evaporator also features adjustable parameters. This allows for customization according to specific materials. Some users appreciate this flexibility, while others struggle with the complexity.

The compact design is noteworthy. It saves space in processing facilities, a crucial benefit for smaller operations. Still, some might find maintenance slightly cumbersome. Regular checks are essential to keep it running smoothly. Overall, these key features contribute significantly to its performance, but some users may face a learning curve.

Advantages of Using Wiped Film Technology in Evaporation

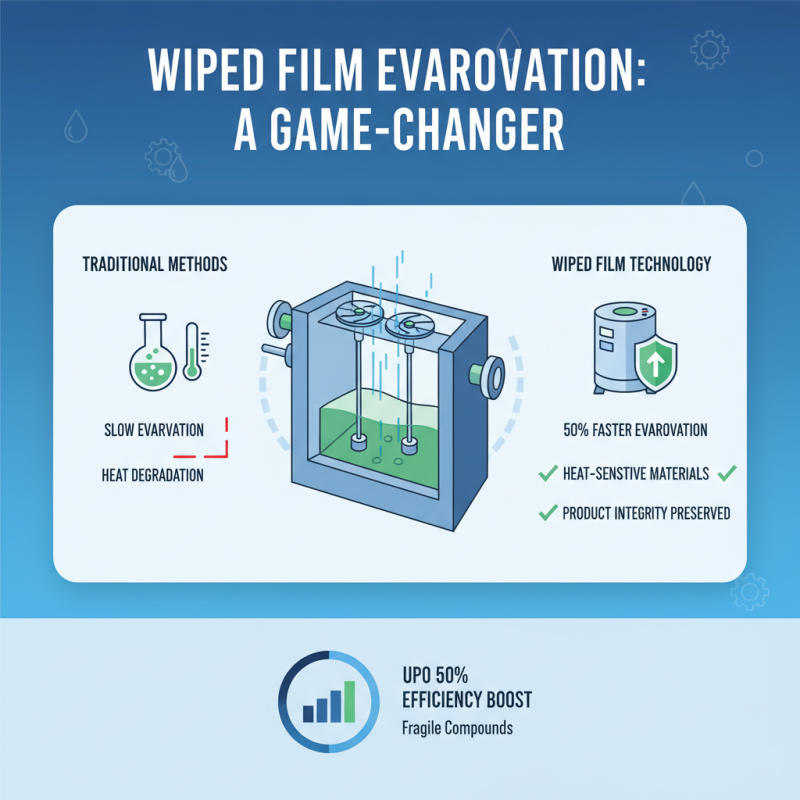

Wiped film technology is a game-changer in the evaporation sector. Its efficiency stands out in processing heat-sensitive materials. Compared to traditional methods, wiped film evaporators can increase evaporation rates by up to 50%. This is crucial when dealing with fragile compounds. The design minimizes thermal degradation, thus preserving product integrity.

One significant advantage is the ability to operate at lower temperatures. This feature can lead to energy savings up to 30%. Additionally, wipe film technology allows for continuous operation, enhancing productivity. A recent industry report highlighted that plants using this technology reported a 20% increase in throughput. Yet, some challenges remain. Equipment maintenance and initial costs can be high. Proper training is essential to maximize its potential. Without skilled operators, efficiency gains can be lost.

The flexibility of wiped film evaporators is another selling point. They can handle a variety of feedstocks, adapting to changing demands. However, this adaptability requires monitoring. Variations in feed composition can affect performance. Continuous optimization is necessary to ensure consistent results. These factors highlight the need for thoughtful implementation and ongoing evaluation in using wiped film technology.

Applications of the 2026 Pfaudler Wiped Film Evaporator

The 2026 wiped film evaporator finds its key applications in various industries. One major area is the food and beverage sector. The equipment efficiently removes water from liquids, which enhances product concentration. This process helps preserve flavors and nutrients. For instance, food extracts are often processed this way to create concentrated sauces or syrups.

Another significant application is in the pharmaceutical industry. The evaporator aids in the production of high-purity solvents and active ingredients. It maintains required temperatures and ensures minimal thermal degradation. However, achieving optimal separation can be tricky. Minor adjustments in parameters may lead to variations in yield and purity.

In the chemical processing industry, this equipment has a critical role. It helps in reclaiming solvents and recovering valuable compounds. But, the challenge lies in scaling operations. Balancing energy efficiency with performance can be complex. Users need to continually assess their processes to achieve desired outcomes.

2026 Pfaudler Wiped Film Evaporator Features and Benefits

This bar chart illustrates the key features and benefits of the 2026 Pfaudler Wiped Film Evaporator, including Thermal Efficiency, Energy Consumption, Operational Cost, Maintenance Frequency, and Product Yield. Each metric reflects the performance advantages that this technology offers in industrial applications.

Maintenance and Operational Guidelines for Optimal Performance

When it comes to maintaining an efficient wiped film evaporator, routine checks are crucial. Check the seals regularly. Worn seals can lead to leaks and reduce overall efficiency. Also, monitor the temperature settings diligently. Inaccurate temperatures can affect product quality.

Tip: Schedule weekly inspections of all components. This proactive approach helps catch issues early, saving time and costs.

Regular cleaning is another essential task. Residue build-up can impact performance and lead to contamination. Use appropriate cleaning agents to avoid damage. However, be cautious. Overcleaning can wear down parts more quickly.

Tip: Keep a log of maintenance activities. This record makes it easier to track patterns and identify recurring problems.

Lastly, operational training is vital for staff. Ensure everyone understands the machine's functions and safety protocols. Misunderstandings can lead to operation errors. Allowing team members to share their experiences can also reveal overlooked areas.

2026 Best Pfaudler Wiped Film Evaporator Features and Benefits Explained

| Feature | Description | Benefits |

|---|---|---|

| High Efficiency Heat Transfer | Utilizes advanced engineering designs to enhance thermal performance. | Reduces energy consumption and improves overall process efficiency. |

| Compact Design | Space-saving architecture suitable for limited floor space. | Enables easy integration into existing facilities and enhances workflow. |

| Versatile Operation | Capable of handling a wide range of feed materials and viscosity levels. | Increases operational flexibility and allows for various applications. |

| Automated Control Systems | Advanced monitoring and control technologies for process optimization. | Enhances reliability and minimizes operator intervention. |

| Robust Construction | Designed to withstand harsh industrial environments. | Ensures longevity and reduces maintenance costs. |

Comparative Analysis with Other Evaporation Technologies

Wiped film evaporators have gained attention in various industries for their unique benefits. Compared to traditional methods, they offer enhanced efficiency. They perform effective separation of volatile compounds while maintaining product integrity. This technology is ideal for heat-sensitive materials. The controlled environment reduces thermal degradation during the process.

In contrast, falling film evaporators may operate faster but lack the same level of product protection. They can be more prone to fouling, disrupting continuous operation. Batch evaporators, on the other hand, struggle with scalability. They often lead to inconsistent product quality, limiting their application. However, wiped film systems are not without their challenges. The initial cost can be higher, and maintenance can become complex.

Some users report a learning curve. The operation requires precise control and monitoring. Mismanagement can lead to suboptimal results. While wiped film evaporators shine in many applications, users must consider their specific requirements. This technology is not a one-size-fits-all solution.

Related Posts

-

Top 10 Benefits of Thin Film Evaporators for Efficient Distillation Processes

-

Top 5 Tips for Using LCI Wiped Film Evaporators Effectively

-

How to Choose the Best Horizontal Thin Film Evaporator for Your Needs

-

2025 Top Film Evaporator Technologies and Trends You Need to Know

-

What is a Thin Layer Evaporator and How Does It Work

-

Top Benefits of Pfaudler Wiped Film Evaporators for Industrial Applications?