Employment Application Apply

Top 10 Benefits and Applications of Pope Wiped Film Evaporator Technology

The Pope Wiped Film Evaporator (PWFE) technology represents a significant advancement in the field of thermal separation processes, widely used in industries ranging from food and beverage to pharmaceuticals and petrochemicals. According to a report by the International Institute of Chemical Engineers, the utilization of wiped film evaporators is projected to grow at a compound annual growth rate (CAGR) of 7.5% through 2025, highlighting the increasing demand for efficient and high-quality separation solutions. This surge in market interest is driven by the need for improved energy efficiency and minimal product degradation during processing.

Experts in the field emphasize the versatility and effectiveness of the Pope Wiped Film Evaporator in various applications. Dr. Sarah Thompson, a leading chemical engineer specializing in evaporative technologies, asserts, "The Pope Wiped Film Evaporator is revolutionary in its ability to handle heat-sensitive materials while ensuring high yields." This statement underlines the evaporator's capacity to operate under gentle conditions that are critical for the preservation of sensitive compounds, thereby making it an essential tool in the formulation of high-purity products.

As industries continue to evolve and demand higher efficiency and purity standards, the Pope Wiped Film Evaporator stands out as a cutting-edge solution that meets these needs effectively. With its ability to enhance operational efficiency and product integrity, it is crucial to explore the top benefits and applications of this innovative technology.

Overview of Pope Wiped Film Evaporator Technology

Pope Wiped Film Evaporator technology represents a significant advancement in the field of thermal separation processes, particularly for the processing of viscous materials and heat-sensitive compounds. The design of wiped film evaporators facilitates a continuous flow of liquid through a heated surface, allowing for efficient evaporation while minimizing thermal degradation. According to industry reports, this technology can achieve evaporation efficiencies upwards of 90%, making it an indispensable tool in sectors such as pharmaceuticals, food processing, and chemical manufacturing.

One of the critical aspects of Pope Wiped Film Evaporators is their ability to operate at lower temperatures and under a vacuum, which effectively reduces the risk of oxidation and degradation of sensitive products. This is especially relevant in the pharmaceutical industry, where maintaining product integrity is paramount. Research indicates that the use of wiped film evaporators can lead to a significant reduction in energy consumption compared to traditional evaporative technologies, with up to 30% less energy required for the same output. This efficiency not only lowers operational costs but also enhances sustainability, making it a preferred choice for environmentally conscious operations.

Understanding the underlying principles and the operational advantages of wiped film evaporators is crucial for industries looking to innovate their processes and improve product quality. The incorporation of this technology aligns with the growing demand for high-purity products and efficient processing solutions in an increasingly competitive market.

Top 10 Benefits of Pope Wiped Film Evaporator Technology

Key Benefits of Using Wiped Film Evaporators in Industrial Processes

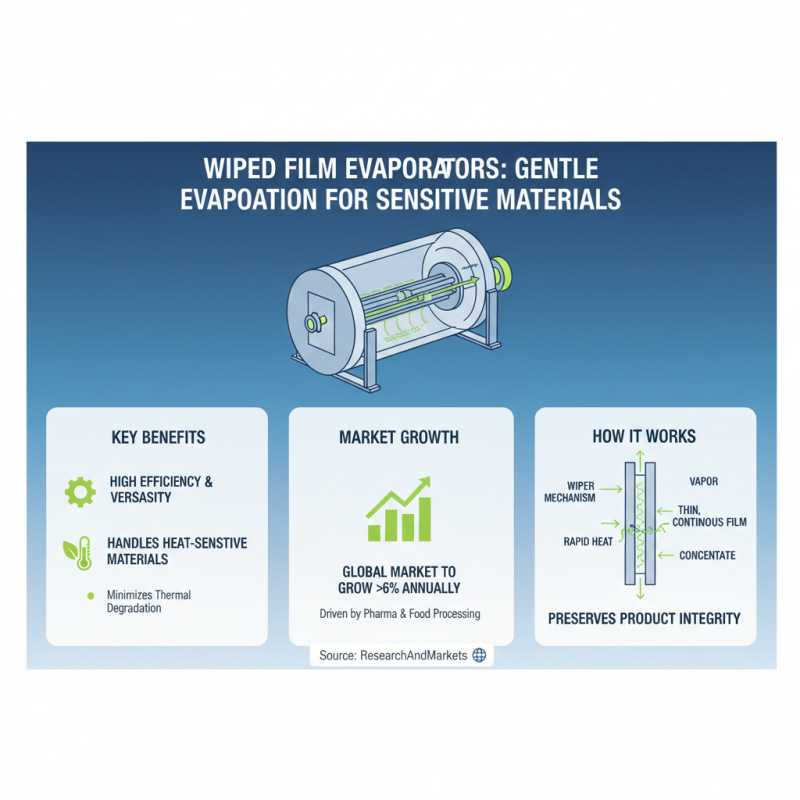

Wiped film evaporators are gaining traction in various industrial processes due to their remarkable efficiency and versatility. One of the key benefits is their ability to handle heat-sensitive materials without compromising quality. According to a recent market analysis by ResearchAndMarkets, the global wiped film evaporator market is expected to grow by over 6% annually, driven largely by the demands of industries such as pharmaceuticals and food processing that require gentle evaporation techniques. The continuous film created by the wiper mechanism allows for a rapid heat transfer, which minimizes thermal degradation and preserves the integrity of the product.

Another benefit of wiped film evaporators is their efficiency in separating volatile components, making them ideal for liquid-liquid and liquid-solid separations in industries like petrochemicals. The technology can achieve separation efficiencies over 95%, according to data from the American Institute of Chemical Engineers. This high efficiency not only maximizes yield but also reduces energy consumption by shortening processing times. Moreover, the design of wiped film evaporators allows for easy cleaning and maintenance, which contributes to lower operational downtime and higher production throughput. As industries continue to seek ways to enhance productivity while maintaining product quality, the adoption of wiped film evaporators will undoubtedly play a significant role in shaping future processing technologies.

Applications of Pope Wiped Film Evaporator Technology in Various Industries

Pope wiped film evaporator technology has found significant applications across various industries, thanks to its efficiency in separating components from liquid mixtures. In the chemical industry, for instance, this technology is employed for the purification and concentration of solvents, often operating continuously to enhance productivity. According to a report by Research and Markets, the global wiped film evaporator market is projected to grow at a CAGR of 5.2% from 2021 to 2026, indicating a rising demand in sectors that require high-purity solvents and ingredients.

Another critical application of wiped film evaporators is in the food and beverage industry, where they are utilized for the concentration of fruit juices and the removal of undesirable volatile components. The evaporators maintain the delicate flavor profiles and nutritional qualities of natural products, aligning with consumer preferences for clean label foods. A study published in the Journal of Food Science indicates that using wiped film technology can reduce energy consumption by up to 25% while maintaining product quality, making it an attractive option for manufacturers seeking to improve sustainability practices.

In the pharmaceutical realm, wiped film evaporators play a vital role in the production of active pharmaceutical ingredients (APIs). The ability to operate under low pressure and temperature minimizes thermal degradation, ensuring the integrity of sensitive compounds. As per a market research report from Grand View Research, the pharmaceutical evaporator segment is anticipated to witness significant growth, driven by the increasing demand for efficient processing technologies that enhance product yield and quality in drug manufacturing.

Comparison of Wiped Film Evaporators with Other Evaporation Techniques

Wiped film evaporators (WFEs) have become increasingly prevalent in industrial applications due to their unique advantages over traditional evaporation techniques. One key benefit of WFEs is their ability to efficiently process high-viscosity fluids, as the continuous movement of the film reduces the likelihood of fouling. According to a report by the International Society of Chemical Engineering, WFEs can achieve evaporation rates up to three times higher than falling film evaporators, making them particularly valuable in industries such as pharmaceuticals and food processing where time and efficiency are critical.

In comparison to rotary evaporators, which commonly rely on reduced pressure to lower boiling points, wiped film evaporators offer a greater operational flexibility. While rotary evaporators are limited in their ability to handle viscous solutions, WFEs can seamlessly handle materials with viscosity values exceeding 100,000 cP. Furthermore, WFEs provide a superior temperature control mechanism, ensuring that sensitive compounds remain intact during processing. As noted by a recent survey from the Chemical Engineering Magazine, over 60% of manufacturers transitioning to wiped film technology reported reduced energy costs, highlighting the potential of WFEs to not only improve yield but also bolster sustainability within the chemical processing sector.

Future Trends and Innovations in Wiped Film Evaporator Technology

The future of wiped film evaporator technology is poised for significant advancements driven by the growing need for efficient and sustainable processing methods across various industries. One prominent trend is the integration of automation and smart technology, which aims to enhance operational efficiencies and reduce human intervention. These innovations will likely include advanced monitoring systems utilizing IoT devices that track real-time performance metrics, thereby allowing for quicker adjustments and optimizing production processes.

Additionally, there is a notable shift towards the development of more energy-efficient and environmentally-friendly systems. Researchers are exploring the use of alternative heat transfer methods and advanced materials that can withstand higher operational loads while minimizing energy consumption. This aligns with the broader industry focus on sustainability, paving the way for wiped film evaporators that not only meet stringent regulatory requirements but also contribute positively to environmental conservation efforts. As these technologies evolve, they will open new applications across food processing, pharmaceuticals, and chemical industries, ultimately transforming how materials are separated and purified.